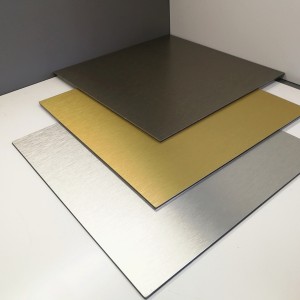

The color in the chart is just for reference. A slight color variation may occur between different products such as different pigments. For exact color matching, please request actual color samples.

Product Properties

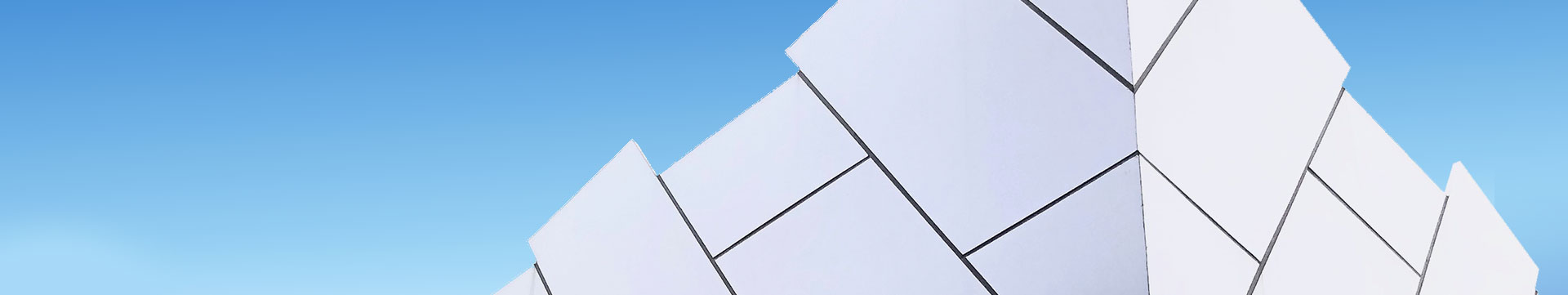

Alucobest® aluminum composite materials (ACP) are produced by continuously bonding two thin aluminum skin on either side of an extruded LDPE or mineral-filled, fire-retardant thermoplastic core. The aluminum surfaces have been pre-treatment and coil-coated in a variety of paint finishes before lamination. We also offer metal composite materials (MCM) featuring skins of copper, zinc, stainless steel or titanium bonded to the same cores with special finish. Alucobest® ACP and MCM both offer the rigidity of heavy-gauge sheet metal in a lightweight composite material.

Ease of Fabrication

Alucobest® ACP can be fabricated with ordinary woodworking or metalworking tools, with no special tools required. Cutting, grooving, punching, drilling, bending, rolling and many other fabrication techniques can be easily performed to create a virtually unlimited variety of complex forms and shapes.

Method of packing

By iron pallet:

In bulk:

By wood pallet: