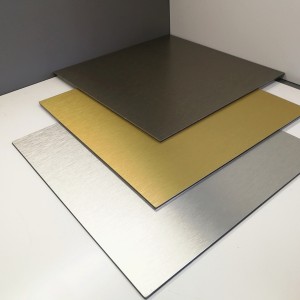

Specification:

Color: Silver, Golden

Panel Thickness:3mm, 4mm

aluminum alloy: 0.30mm

Standard Size:1220*2440mm

Core: normal PE,A2, FR

Applications:

Sign Making

Interior Decor

Retail/Industrial Design

Exhibition Stands

Features:

Strong metallic feeling

Tough as nails

Remarkably impervious

Good scratch resistance

No corrosion

Cost-efficient alternatives of copper, brass, zinc etc...

PE a premium quality aluminum composite panel with a LDPE(Low-Density Polyethylene) core sandwiched between two skins of 0.30,0.40 or 0.50mm thick aluminum sheets. It is suggested to be used as the exterior,interior cladding and roof covering on new low buildings.

FR made with a mineral fire retardant (FR) core sandwiched between two skins of aluminum sheets. Due to its hardly inflammable mineral-filled core, ALUCOBEST fr can meet the higher requirements of the fire regulations. It achieves Class B-s1,d0 according to EN13501-1 standard.

A2 a non-combustible aluminum composite panel usded in facade worldwide. ALUCOBEST A2 is composed of natural inorganic mineral-filled core sandwiched between two skins of aluminum sheets. Due to its non-combustible mineral-filled core, ALUCOBEST A2 meets the highest requirements of the fire regulations. It achieves Class A2-s1,d0 according to EN13501-1 standard.

Product Properties

The Alucobest Anodized Aluminium Composite Panel comes out from an electrolyte process and lamination process.

The electrolyte process offers the exceptional hardness of the aluminium and maintains the intrinsic brilliance of metallic property.

Ease of Fabrication

Same as the easy processing and fabricating properties as the normal aluminium composite panel.

There is no limit to be slotting, curved, punched, laser engraved, embossed etc...Thus it can be easy to fabricate and suitable for virtually any exterior and interior cladding.

Total Quality Management

Raw Material Test

IPQC,In Process Quality Control

Pre-Shipment Inspection(PSI)

Raw Material Test

IPQC,In Process Quality Control

Pre-Shipment Inspection(PSI)